A tapestry’s long road to recovery!

July 3, 2023 | Treasure tales and archive snippets | 6 minute read

Earlier this year, we finally rehung an 18th Century English Soho tapestry along the passageway to the Chapel. This tapestry suffered water damage in 2017 and it has been a six-year long road to conserve and restore the work and see it rehung in its rightful home! Katherine Hardwick, Collections Coordinator here at Holkham, gives insight into what’s been going on over the last six years.

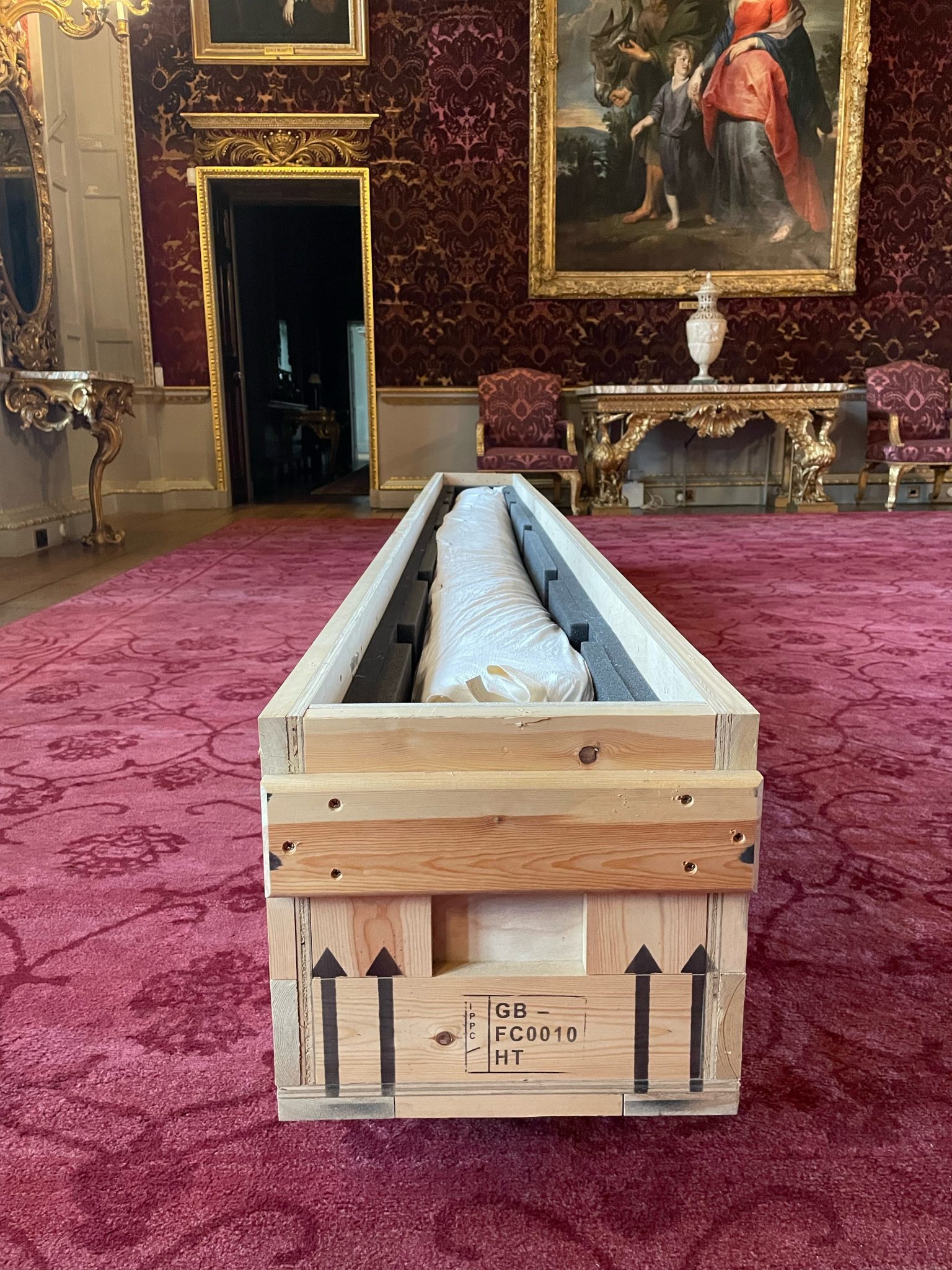

This story begins way back in late 2017, when the tapestry in question was water-damaged by a burst pipe, and the long process of conservation began. The first port of call was to remove the tapestry from the wall, which was not as easy as it sounds. The work was hung above a stair, and so we had to install a double-platform scaffold. Once off the wall, the hangings, lining and webbing were removed and the tapestry was vacuumed with a special low-suction vacuum cleaner to take off the surface dust before being carefully wrapped ready for transport.

The first stop on the tapestry’s journey was the Royal Tapestry Manufacturers, De Wit, who are based in Mechelen, Belgium. The facility at De Wit has a specially constructed chamber for wet cleaning tapestries, which is a difficult and delicate process. If you have ever washed a beloved (or expensive!) piece of knitwear, you’ll have faced the same problems: will the dye run? What if the detergent damages the fibres? How do I dry it without stretching it? Now multiply those problems to the size of a 3m x 5m tapestry, and you’ll understand why these items are not washed very often!

The tapestry was laid flat onto a huge vacuum suction floor, complete with a low, moveable, metal bridge giving the conservators access to the centre of the work. The suction helps to both keep the tapestry in place and to pull the water and detergent through more effectively. Colour testing was carried before cleaning to identify the best ratio of water and detergent for the specific item. The actual cleaning process involved washing the tapestry with water and a soft detergent, then brushing with soft brushes and rinsing thoroughly. After rinsing, it was blotted with specialist towels to remove excess water, then left to dry for 2-3 hours. The entire cleaning process lasted 12 hours! We were thrilled to hear that the cleaning had been successful, and that the tapestry was in really good condition. The tidemark from the burst water-pipe had been removed during the cleaning, alongside 270 years of dirt and dust.

Overseeing this process on behalf of Holkham was Rachel Langley, Senior Textile Conservator at the National Trust Textile Conservation Studio, based at nearby Blickling. Both Rachel and the Textile Studio have worked with us on projects in the past, including netting the State Bedroom coverlet and upholstering various items of furniture.

The dirt from cleaning the tapestry

Once the tapestry had been cleaned, dried, and returned to Norfolk, the next step was to strengthen the tapestry warps. Warps are the structural threads which silk is woven around to make an image. On a tapestry, the warps are horizontal, meaning that the weight of the tapestry hangs on the warp; over time, this weight causes the warps to sag, exposing small slits which are formed during weaving, used to create a shadowing effect or to make a stark contrast between two colours. The original weavers would have sewed these slits shut, and so the second stage of the project was to re-close them.

Working on such a large and fine tapestry was delicate and time-consuming work, in which we were ably assisted by volunteers from the Arts Society, King’s Lynn. They were given training by Rachel Langley, who was on hand to support throughout the process. They began with us in September 2019. Six months later, the whole country was locked down for the first time. Between the various lockdowns, isolation periods, and other planned hiatuses, the sewing was not completed until Christmas 2021.

Phase 3 also involved the Arts Society, this time attaching new ‘galloons’ to the tapestry. Galloons are simply the long, plain borders that can be found at the edge of any tapestry; the ones on this work had been attacked by moths at some point in its 270-year history, and a helpful individual had darned the moth holes. Unfortunately, the thread they had used to darn the holes was less light-fast than the original fabric, meaning the galloons presented an almost patchwork effect. New galloons were attached over the top of the old galloons, so should future curators wish to return to the original, they are able to do so.

Galloons

Phase 4 was just about the last bit of work to be carried out on the tapestry, with the conservators at the Textile Studio relining the work in cotton cambric to protect it from dust and insects. The work was finally rehung in March 2023, using the same double-platform scaffold used to deinstall it only six years ago.

This tapestry is a part of a set, with the other pieces hanging in the Stranger’s Wing. You can read all about the history of these tapestries, and their amazing, innovative design here.